Hot work jobs, like welding or cutting, can spark serious fire risks in seconds. That’s why OSHA hot work fire watch requirements are so strict when it comes to permits, site prep, and post-work monitoring.

In this post, you’ll learn what those requirements are, how to stay compliant, and what to do when timelines are tight but the rules still apply.

TL;DR: OSHA Hot Work Fire Watch Requirements at a Glance

- OSHA requires hot work authorization before any cutting, welding, or torch use, ideally through a written permit that outlines safety measures.

- A fire watch is required when there’s potential for more than a minor fire or if combustibles, wall openings, or opposite-side hazards exist within 35 feet of the hot work area.

- The minimum fire watch duration is 30 minutes after work ends, as per OSHA 1910.252; however, many jurisdictions now follow NFPA 51B, which requires 60 minutes or more, depending on the risk.

- Construction sites must follow 1926.352 rules, including special limits for impaired sprinklers or flammable atmospheres.

- Confined spaces may require both a hot work permit and a confined space permit.

- In EPA RMP-covered facilities, a written hot work permit is mandatory and must document all fire-prevention controls under OSHA 1910.252.

Why Hot Work Compliance Isn’t Optional

Hot work is one of the leading causes of jobsite fires, and most of them start from something small. A spark lands in the wrong spot, a wall cavity isn’t sealed off, a guard forgets to stick around long enough. That’s all it takes.

This is why OSHA requires proper authorization, fire prevention controls, and a fire watch in place. And why local inspectors look closely at your permit, your post-watch timing, and whether you followed the 35-foot rule.

Failing to follow the rules doesn’t just risk safety; it also compromises it. It can shut down your site, delay your project, or bring fines you didn’t budget for. Getting it right from the start keeps your people safe, your schedule intact, and your liability low.

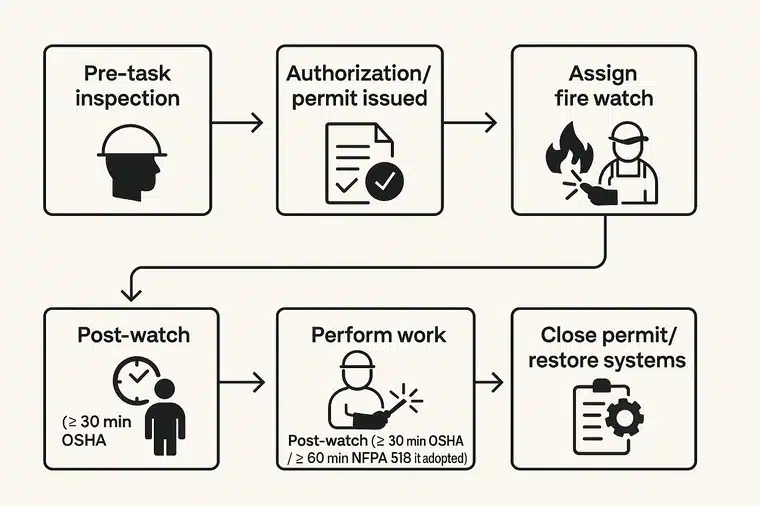

How OSHA Hot Work Permits Work (Step-by-Step)

A hot work permit isn’t just a form; it’s a documented process to prevent fires before, during, and after the job. Here’s how it works under OSHA 1910.252, plus key overlaps with NFPA 51B, 1926.352, and confined space rules.

Step 1. Authorize the Job

Before any welding, cutting, or torching begins, a responsible person must inspect the area and approve the work to be done. While OSHA allows verbal authorization, a written permit is strongly recommended and mandatory in certain facilities, like EPA RMP-covered sites.

Step 2. Prepare the Area

- Remove combustibles within 35 feet, or cover them with flame-resistant blankets.

- Seal openings in walls, ceilings, and floors.

- Block off ducts or pipes that could carry sparks.

- Place fire extinguishers nearby and verify they’re charged.

- Control airflow and ventilation if flammable vapors are present.

The 35-foot rule applies to nearby walls, storage areas, and even the opposite side of a shared wall if heat can transfer.

Step 3. Assign Fire Watch

A trained fire watch is required when:

- A fire could easily start,

- Combustibles are present within 35 feet,

- Wall openings or floor penetrations exist, or

- There’s potential for heat transfer to hidden spaces.

The fire watch must:

- Remain on-site during hot work,

- Stay for at least 30 minutes after work ends (OSHA minimum),

- Have extinguishing equipment and know how to use it,

- Be able to sound an alarm if needed.

Many AHJs now follow NFPA 51B, which requires a minimum of 60 minutes of post-watch time, so they apply the stricter rule.

Special Situations

- Construction sites: Follow 1926.352, especially if sprinklers are impaired or flammable gases are nearby.

- Confined spaces: You’ll likely need both a hot work permit and a confined space entry permit.

- EPA RMP sites: A written hot work permit is mandatory, so keep it on file until the job is completed.

What to Document on a Hot Work Permit (and Why It’s Important)

A permit isn’t just a form to check off; it’s what protects you if there’s an inspection, audit, or worse, a fire. Here’s what should be recorded every time hot work takes place:

Work Details

- Exact location of the hot work (room, floor, area ID)

- Scope of work — cutting, welding, brazing, grinding, torching

- Start and stop times for both the work and the fire watch

- Date and responsible parties

Why it’s important: This info shows the fire marshal or AHJ that you knew exactly what was happening and where.

Safety Controls in Place

- Distance from combustibles (or how they were protected)

- 35-foot clearance or shielding used (blankets, curtains, shields)

- Openings sealed — walls, floors, ducts

- Extinguishers staged and ready — list type (CO₂, ABC, etc.)

- Ventilation checked — particularly for confined or vapor-heavy areas

- Blanking or isolation steps — if applicable in piping or tanks

Why it’s important: These are the controls OSHA and NFPA expect to see. If they’re not documented, they didn’t happen, at least in the eyes of compliance.

Assigned Personnel

- Permit authorizer’s name and signature

- Hot work operator(s) — name and role

- Fire watch name and contact

- Time fire watch started and ended

You may also see the term PAI (Permit Authorizing Individual) in NFPA 51 B. This is the person who makes sure all controls are in place before work begins.

Final Checks

- Time of last inspection

- Post-watch duration (e.g., “60 min” if AHJ uses NFPA 51B)

- Permit close-out signature

- Notes for re-entry, follow-up, or if the site is handed off to another team

Why it’s important: This confirms that someone stayed after the last spark flew. AHJs often flag permits missing fire watch end times or final sign-off.

| 📝 Pro tip: If you want to keep it simple, create a laminated cheat sheet for your team with a checklist for permit fields and fire watch log entries. Keep it near the torch setup or control room. Inspectors love seeing that kind of readiness. |

Operational notes (timelines, processes, AHJ differences)

The rules don’t stop once the torch shuts off. Post-work timing, permit requirements, and local fire codes can vary depending on where and how the hot work is performed. Here’s what to know:

- OSHA baseline: A fire watch must remain on site for at least 30 minutes after hot work is completed. This is OSHA’s national requirement for general industry settings under 1910.252.

- NFPA 51B (2019): Many Authorities Having Jurisdiction (AHJs) now adopt this stricter fire code. It sets a minimum 60-minute post-watch requirement, and in higher-risk cases, the permit authorizing individual (PAI) may require up to 3 hours of extended monitoring. [Confirm local adoption]

- Construction sites: Apply 1926.352 standards. Hot work must not proceed in areas with impaired fire sprinklers or where flammable vapors, liquids, or dust are present. This includes active renovation zones, unventilated shafts, or areas with open chemical containers.

- Confined space overlap: If hot work happens inside a permit-required confined space, you’ll likely need both a hot work permit and a confined space entry permit. Each must document separate controls, including ventilation, gas testing, rescue readiness, and fire watch placement.

- RMP facilities (EPA-regulated): For any facility covered under the EPA’s Risk Management Program (RMP), a written hot work permit is explicitly required. This permit must document all safety measures outlined in 1910.252, and it must be retained on file until the work is fully completed.

How Fast Fire Watch Guards Supports Hot Work Compliance

Here’s what you can expect when we’re covering your site:

- Fast dispatch nationwide: Hot Work Fire Watch Services are available 24/7. In most areas, our licensed guards can be on-site in under three hours..

- Trained and equipped professionals: Every guard is trained in OSHA 1915, NFPA 51B, and local fire codes. They show up in uniform, ready with radios, PPE, extinguishers, and logbooks.

- Documentation inspectors trust: We keep complete shift logs with timestamps and location details, so you’ll have proof on hand during audits or walk-throughs.

- Simple coordination: You get one point of contact, real-time status updates, and detailed shift reports delivered without delays.

Clarifying Common Fire Watch Misunderstandings

Some situations feel like a grey area, but the code often has a clear direction. These are some of the most frequent gaps we see in the field:

- Clearing 35 feet of visible combustibles doesn’t always remove the risk. If there are nearby wall cavities, air ducts, or structural voids, fire watch is still required.

- Even if OSHA’s baseline is 30 minutes after work ends, many jurisdictions use NFPA 51 B as their standard. That means fire watch should stay for 60 minutes or longer, depending on risk. Always check your AHJ’s requirements.

Example: Welding near a corridor with interior wall insulation and return air vents triggered a full 60-minute fire watch under local code. Shielding was applied, and the end time was documented in the permit log.

Scaling & advanced practices

Once you’ve got your basic hot work safety plan locked in, it’s time to level up. These practices reduce friction across job sites and help you stay ahead of audits:

- Standardize your permit-to-work system so every site follows the same rules.

- Train supervisors or leads to act as Permit Authorizing Individuals (PAIs), ready to issue or deny permits confidently.

- Digitize your logbooks for faster reporting, centralized documentation, and easier compliance tracking.

- Set up on-call fire watch coverage in advance for high-risk outages, weekend work, or late shifts.

Who Benefits Most from Hot Work Fire Watch

Commercial Fire Watch Services make it easier to stay covered during tenant renovations, night shifts, or when internal staffing falls short.

Here’s who benefits the most by setting clear fire watch and permit protocols:

- Facilities Manager (Manufacturing): Oversees welding during equipment maintenance and depends on trained fire watch to monitor high-traffic zones or compact, high-risk areas.

- Roofing General Contractor: Torch-on roofing near occupied spaces requires a strict 60-minute fire watch and fast, compliant permitting.

- Mechanical Contractor: Soldering or brazing inside plenum spaces and shafts introduces hidden ignition risks. You’ll need fire watch with a clear view and quick response.

- Property Manager (Mixed-Use): Tenant renovations often bring hot work into shared areas like lobbies or mall corridors. A proper fire watch helps prevent costly shutdowns or fines.

Final Word

Hot work safety isn’t just about compliance. It’s about keeping people safe, operations uninterrupted, and regulators off your back. Whether you need urgent coverage, want help structuring a permit-to-work system, or simply need someone to walk you through the requirements, Fast Fire Watch Guards can help.

→ Read next: When Is a Fire Watch Needed in Welding?

Frequently Asked Questions

Is a written hot work permit required by OSHA?

Not always, but it’s strongly advised. OSHA expects clear authorization before hot work begins and typically recommends written permits. If you’re working inside an EPA RMP-covered facility or a high-risk environment, a written permit is non-negotiable.

What exactly triggers a fire watch?

A fire watch is triggered if combustibles are within 35 feet of hot work, there are wall/floor openings nearby, or conditions make it possible for a fire to start and go undetected. It’s also mandatory when systems like sprinklers are offline.

How long should a fire watch remain after hot work?

OSHA requires a minimum of 30 minutes. However, NFPA 51B, now adopted in many cities, calls for at least 60 minutes, sometimes longer, depending on the project’s risk profile. Always follow your AHJ’s rule if it’s stricter.

Which OSHA standard applies to my job — 1910 or 1926?

It depends on the type of work. General industry falls under 1910.252. Construction sites follow 1926.352. Know your category so you’re applying the correct rules.

Do confined space jobs need two permits?

Yes, in most cases. If you’re welding, cutting, or grinding in a confined space, you’ll need both a confined space permit and a hot work permit.

How long do I need to keep my hot work permits?

For jobs inside EPA Risk Management Program-covered facilities, keep permits on file until the work is complete. In all other cases, follow internal company policy or your AHJ’s recordkeeping rules.